Printed circuit board (PCB) assembly

Professional production of electronics from sample to serial production. We can handle the production of piece series up to medium-sized series (thousands of pieces). We have a team of experts who have been active in the industry for 20 years. We offer complete production from PCB assembly to assembly of mechanical parts and to packaging. We also produce custom-made cables.

We have the following machinery at our disposal:

Screen printing equipment

- Printing area: max 410 x 390 mm

- PCB size: max 460 x 410 mm

Camera centering Unique automatic centering system through the template aperture directly in the print position, there is no mechanical movement of the table between centering and printing.

Separation speed and distance Separation of the template from the PCB using a pneumatic-hydraulic system ensures smooth acceleration of the table without vibrations. This ensures the best result when printing the smallest chip components, densely embedded PCBs. The speed and the distance are programmable.

Assembly machine

- Assembly accuracy: ± 0.02 mm (repeatable positioning accuracy)

- Range of components:

- at least 0201

- TQFP240 (35x35mm)

- BGA and QFN

- PCB size: 350 x 400 mm

Soldering equipment

- Automatic remelting furnace

- Maximum PCB size: 400 x 470 mm

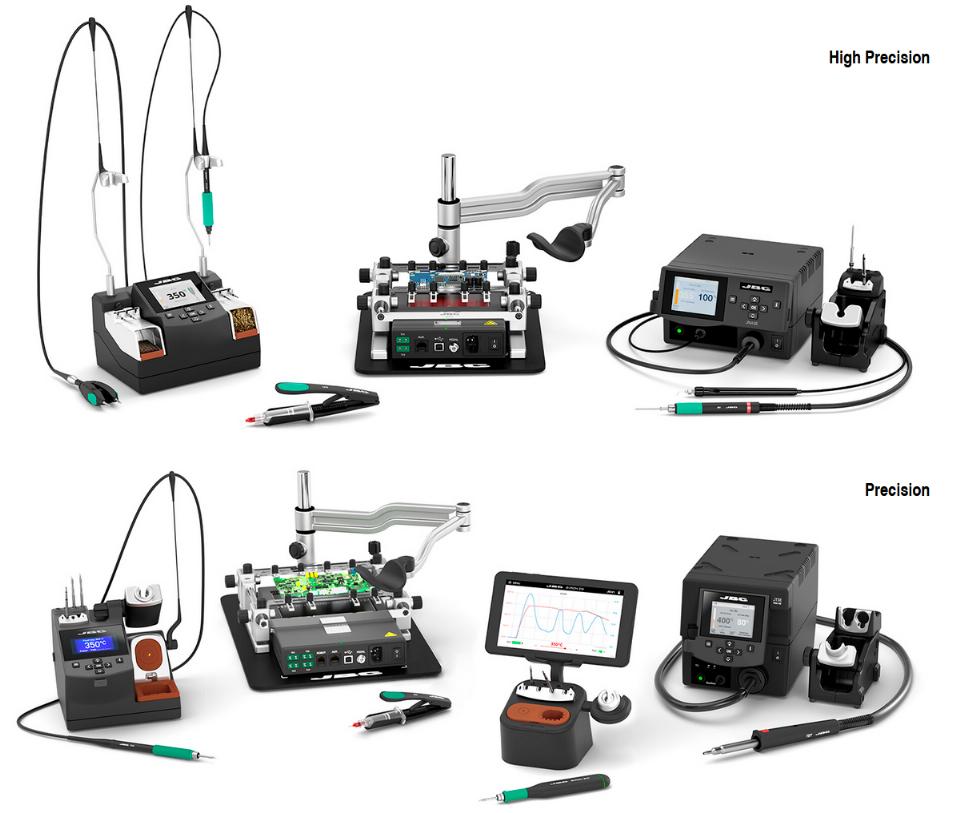

- JBC hand soldering and desoldering stations

PCB washing

Cleaning equipment designed for washing of PCBs. Washes electronic assemblies from flux residue after soldering. The quality of the washing solution and the rinsing with distilled water is controlled by measuring the pH and conductivity.